What Industry Type is Injection Blow Molding Suitable for?

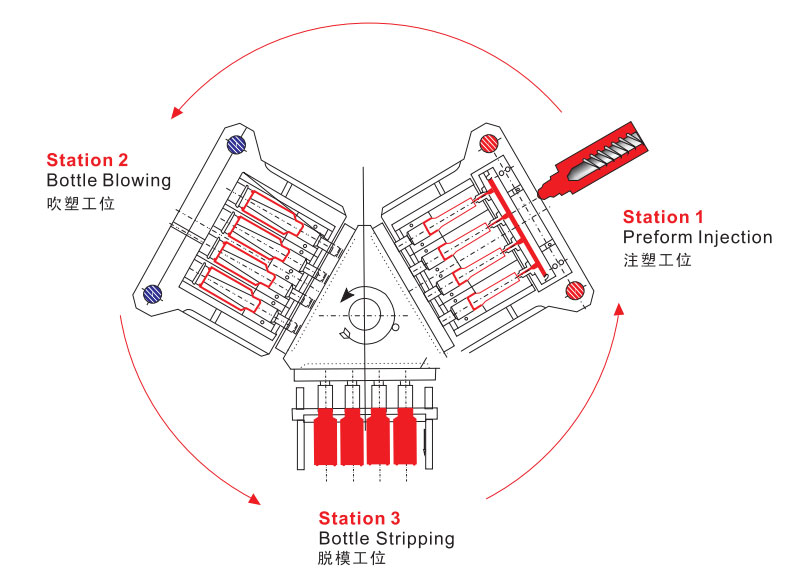

Plastic products are everywhere, shaping how we live and work. But do we really know how they are made? Injection blow molding plays a crucial role in multiple industries, offering precision and efficiency.

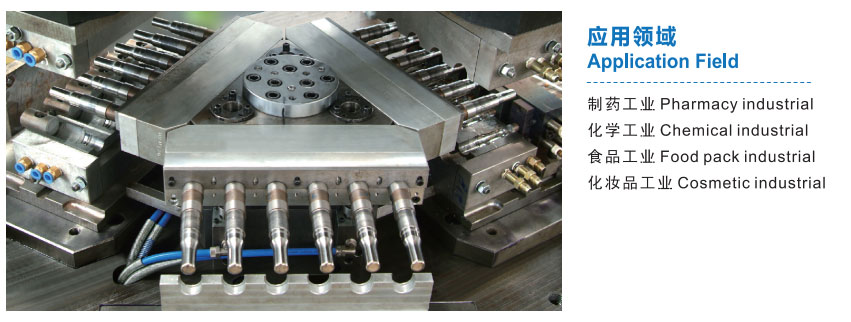

Injection blow molding is widely used in industries such as food packaging, cosmetics, pharmaceuticals, chemicals, and automotive manufacturing. It enables the production of high-quality hollow plastic containers with excellent strength, durability, and customization options.

Its flexibility makes it a preferred method for manufacturers aiming to produce consistent, lightweight, and cost-effective plastic products. Let’s explore how different industries benefit from injection blow molding technology.

What are the Different Requirements for Injection Molding in Different Industries?

The requirements for injection blow molding vary across industries. Manufacturers must consider factors such as material properties, product durability, and safety standards.

Different industries demand specific materials, designs, and processing conditions to meet product functionality and safety requirements. The right injection blow molding approach ensures cost efficiency and product reliability.

Key Industry Considerations

| Industry | Requirements |

|---|---|

| Food & Beverage | Food-safe materials, high barrier properties, airtight sealing |

| Cosmetics & Personal Care | Aesthetic appeal, durability, chemical resistance |

| Pharmaceuticals | Sterile production, chemical stability, precise dosing |

| Chemicals & Industrial | High impact strength, corrosion resistance |

| Automotive | Heat resistance, impact strength, weight reduction |

Understanding these requirements helps manufacturers select the best materials and optimize the molding process for each sector.

Which Industry is the Most Commonly Used for Injection Blow Molding?

The food and beverage industry is one of the largest users of injection blow molding. It relies on this technology for safe and efficient packaging.

Food and beverage manufacturers use injection blow molding to produce bottles, jars, and containers with precise dimensions, ensuring hygiene, freshness, and durability.

Why Food & Beverage Dominates

- Regulatory Compliance: Materials must meet FDA and EU food-grade standards.

- Mass Production Efficiency: High-speed manufacturing ensures cost savings.

- Customization: Unique shapes and branding elements enhance consumer appeal.

- Extended Shelf Life: Barrier properties protect against contamination and spoilage.

Other industries, such as cosmetics and pharmaceuticals, also depend heavily on injection blow molding for high-quality packaging solutions.

What are the Products of Injection Blow Molding in Various Industries?

Injection blow molding is used to manufacture a wide range of products across industries, each requiring unique specifications.

Injection blow molding creates diverse products, from everyday household items to highly specialized medical containers, ensuring durability, safety, and precision.

Industry-Specific Products

| Industry | Common Products |

|---|---|

| Food & Beverage | Juice bottles, milk bottles, condiment containers |

| Cosmetics & Personal Care | Shampoo bottles, lotion containers, perfume bottles |

| Pharmaceuticals | Medicine bottles, dropper bottles, reagent containers |

| Chemicals & Industrial | Lubricant containers, pesticide bottles, chemical storage tanks |

| Automotive | Coolant tanks, windshield washer fluid reservoirs |

Each product is designed to meet strict performance and safety standards within its respective industry.

Can Injection Blow Molding Be Used in More Industries in the Future?

With advancements in materials and processing techniques, injection blow molding is expanding into new applications.

The future of injection blow molding lies in material innovation, automation, and sustainability, allowing it to penetrate emerging industries and support circular economy initiatives.

Expanding Possibilities

- Eco-Friendly Packaging: Biodegradable and recycled plastics are becoming more popular.

- Electronics: Lightweight casings and enclosures for electronic devices.

- Medical Innovations: Sterile and high-precision packaging for sensitive drugs and devices.

- Smart Manufacturing: AI-driven quality control and automation reduce production waste.

- Aerospace & Defense: High-performance, lightweight components for specialized applications.

As industries shift toward sustainable and high-performance materials, injection blow molding will play a larger role in manufacturing.

Conclusion

Injection blow molding serves key industries, from food and cosmetics to automotive and pharmaceuticals. As technology advances, its applications will continue to grow, driving innovation and efficiency across multiple sectors.